ASCA - double piston screen changer

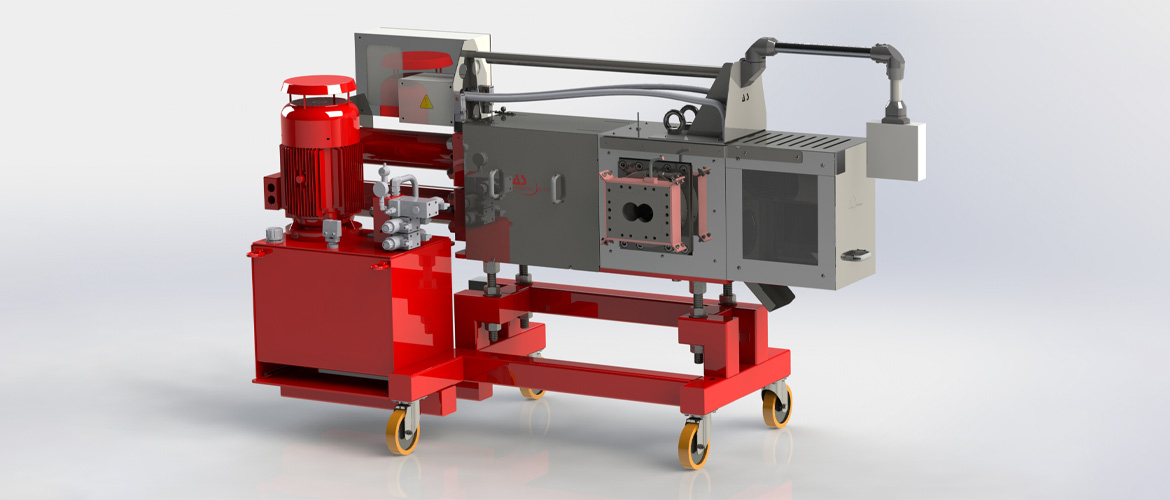

A compact continuous diverter screen changer, modular designed with integrated diverting function. ASCA diverter screen changers combine function of diverter valves and "normal continuous double piston screen changers", new designed for maximum reliability.

Advantages

- integrated diversion-, bypass function (no sep. diverter valve with hydraulic unit necessary)

- especially recommended for underwater pelletizing processes

- process advantage caused by short flow length in opposite to a "2 unit (solution screen changer + diverter valve")

- extremly short Start- / Stop- switching times, resulting from minimized, short switching strokes of the new constructional design

- maximum reliability, caused by very short switching strokes and use of hydraulic systems with 2 movement speeds (only switching strokes fast moved)

- minimized elektric power consumtion, especially for hydraulic system in opposite to similar system in the past

- diverting-, bypass channel restrictable variably for processing low viscous products

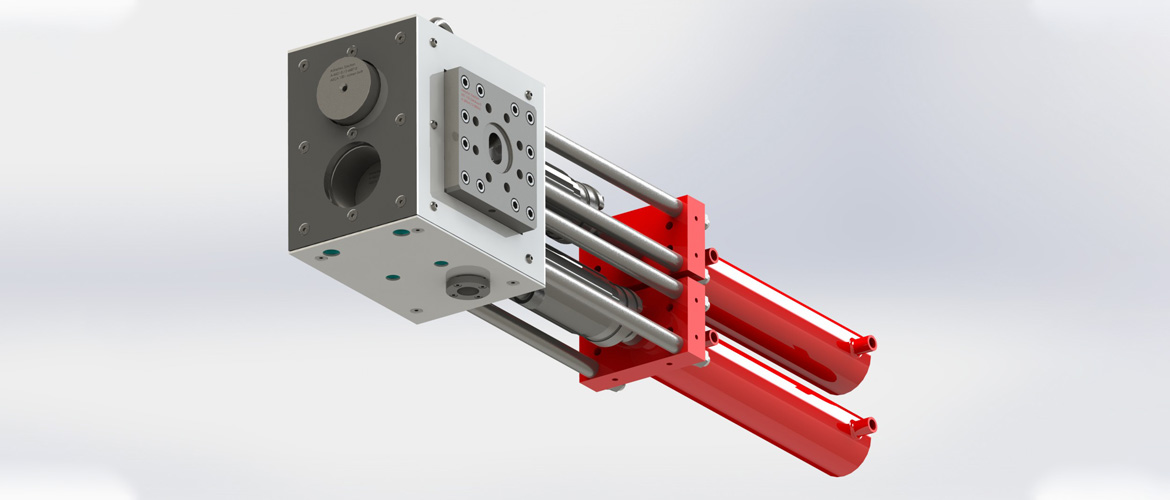

- both screen bolts (upper / lower) identically executed

- often no or only short additional adapters / adapter rings necessary for line installation

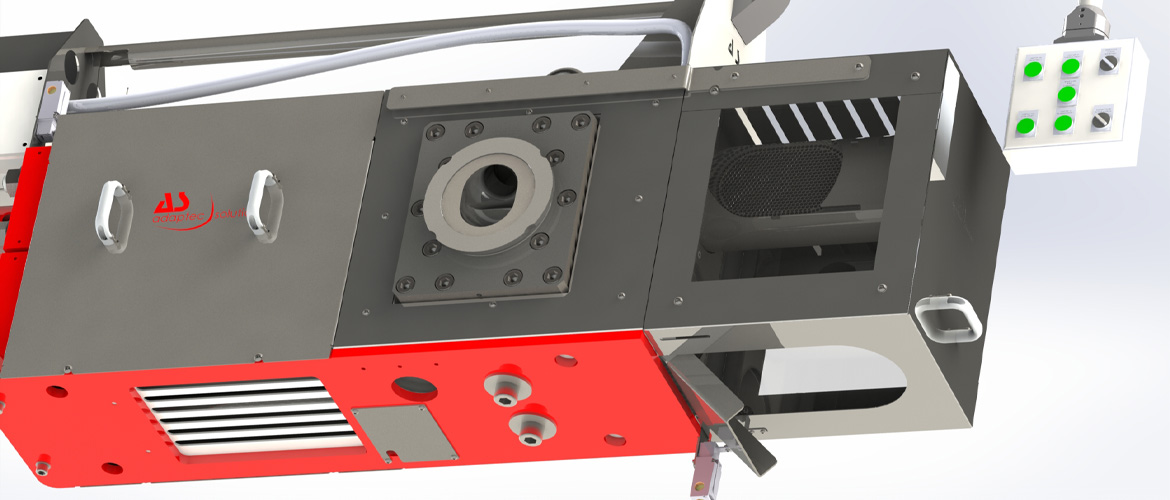

- melt inlet and outlet melt dividing parts are disassembable for easiest inner complete cleaning

- melt sensor borings includable to screen changer without additional costs

- optimized, individual connection dimension executable without additional costs

- upper and lower screen bolt in equally execution (compatibility)

- straight, dead space free streaming of screen cavities from ahead, thereby no danger of screen displacing by angular melt flow

We offer the following ASCA screen changer types

- with / without base frame / movable stand

- with / wthout hydraulic unit

- with / without elektric hydraulic control

- with/ without heating control system

- with / without peripherial equipement (e.g. discharge tool)

- with special heat treatments or special coatings for abrasive and / or korrosive, also "HT" (high temperature application) until 842°F (450 °C)

- of course also deliverable as self-sufficient operational complete system