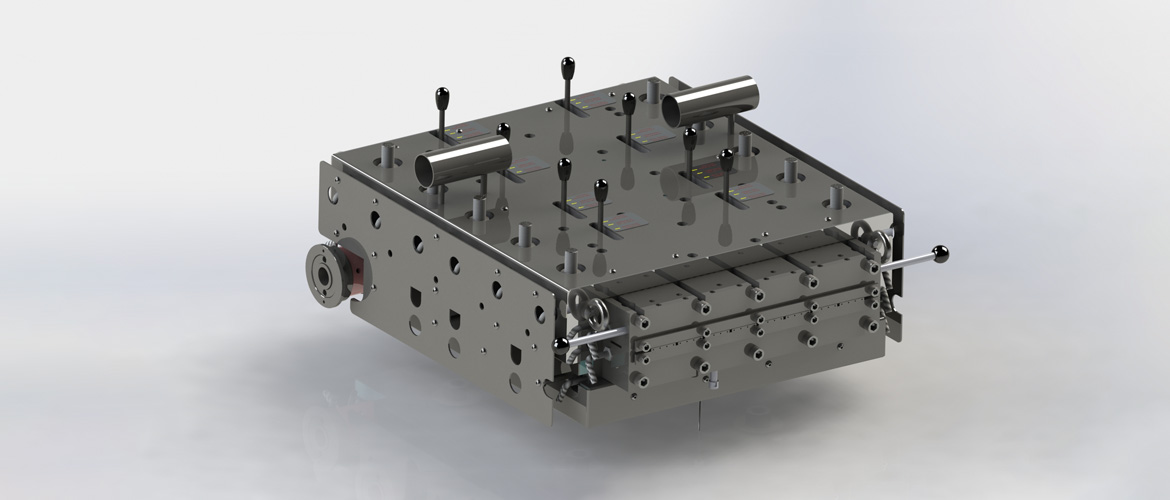

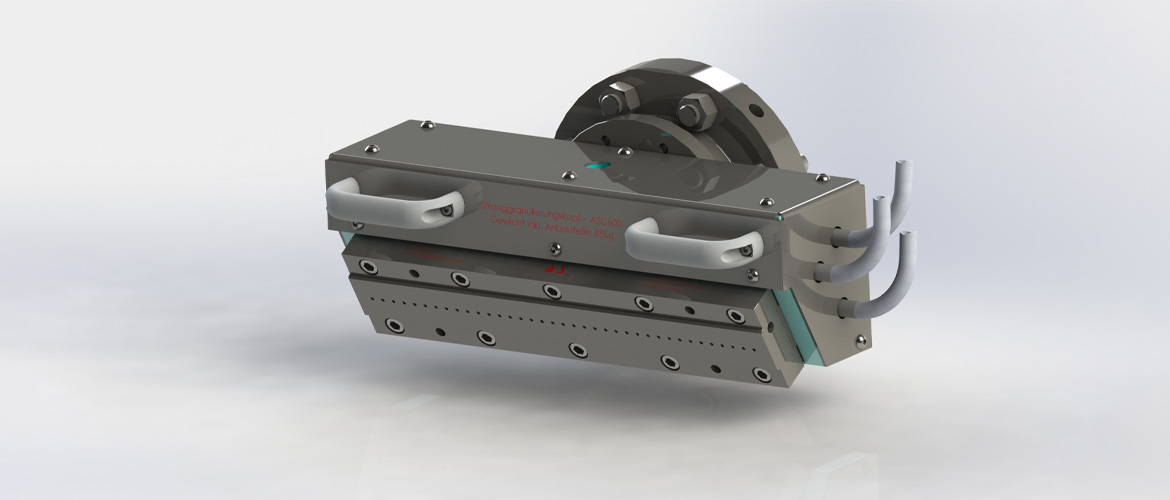

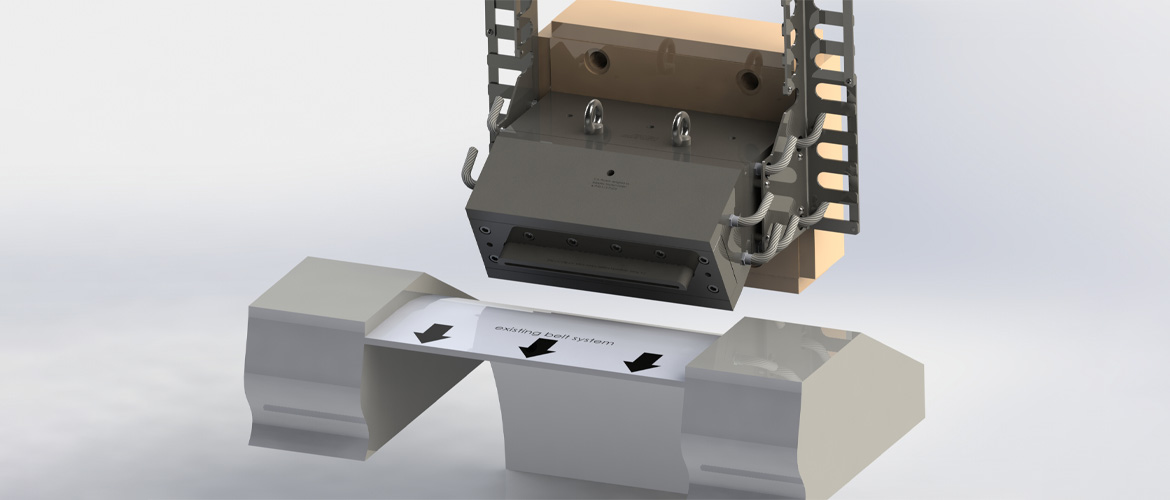

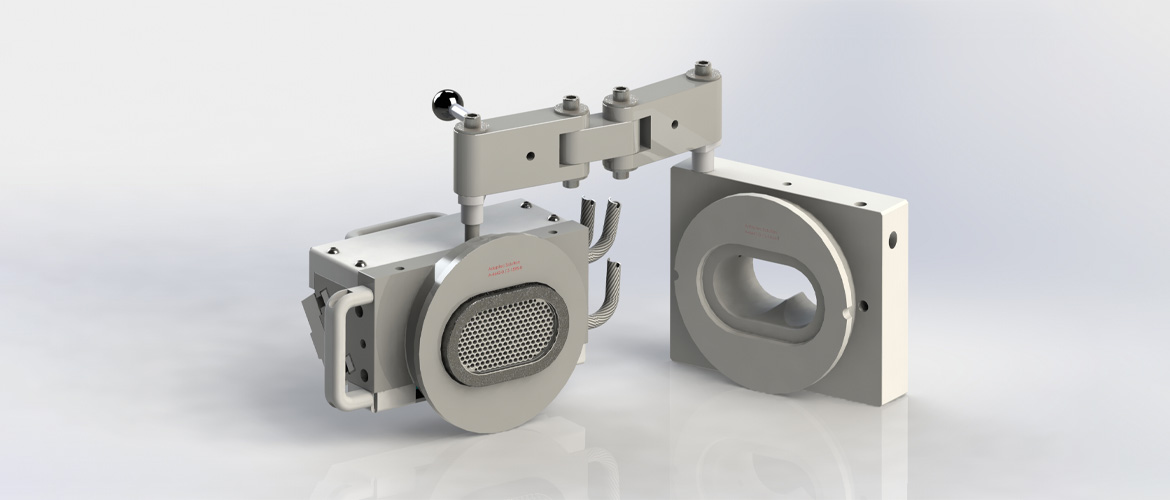

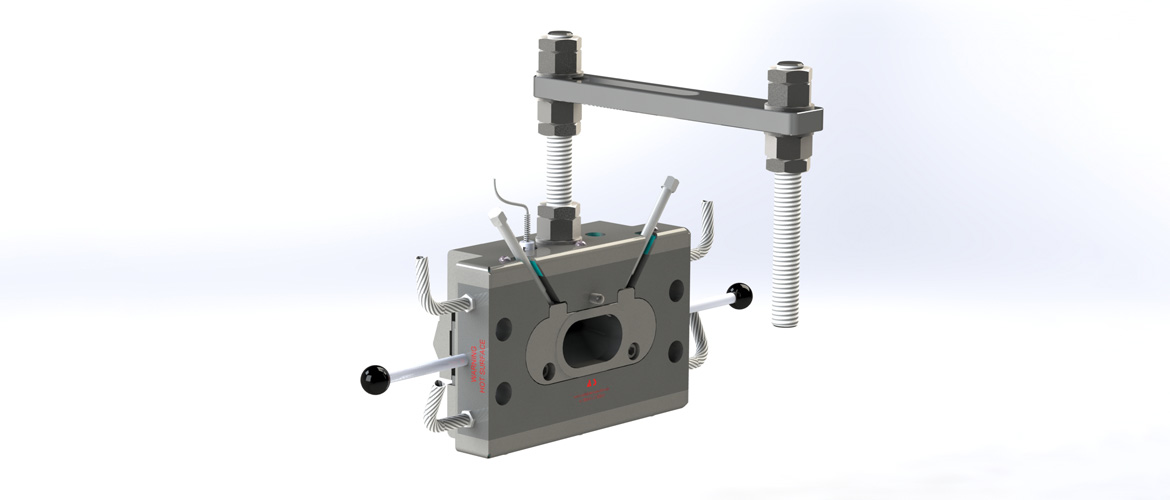

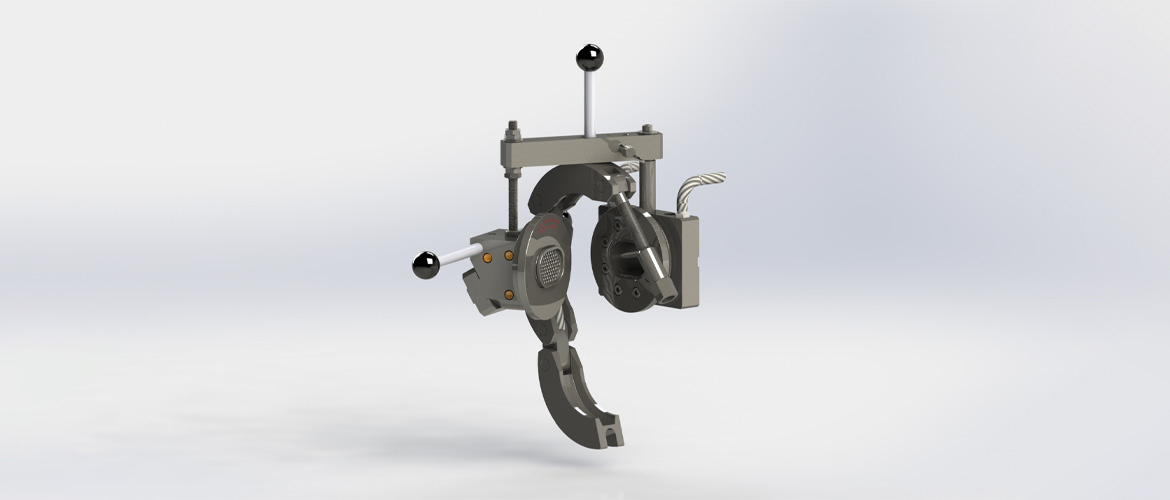

Die head / discharge tools

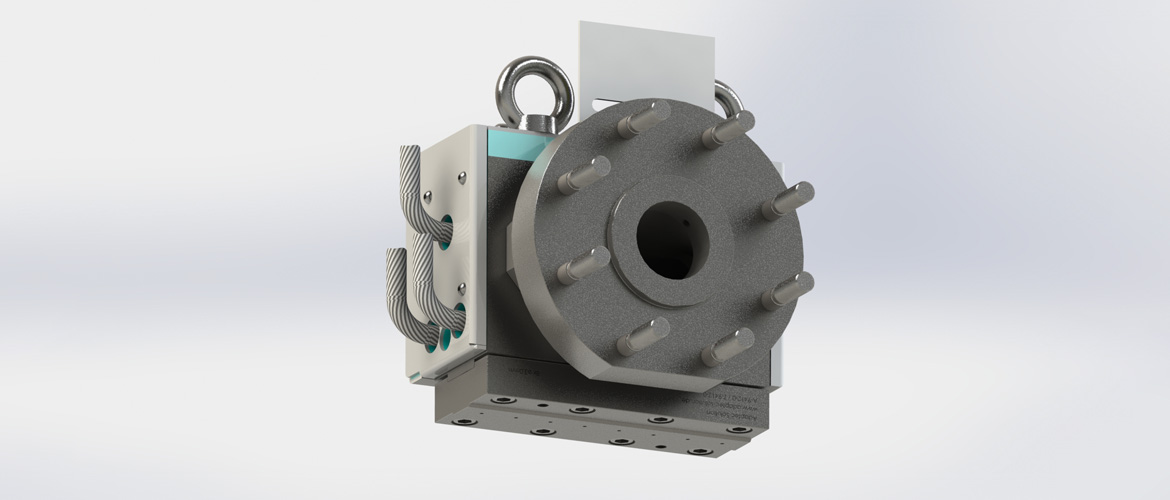

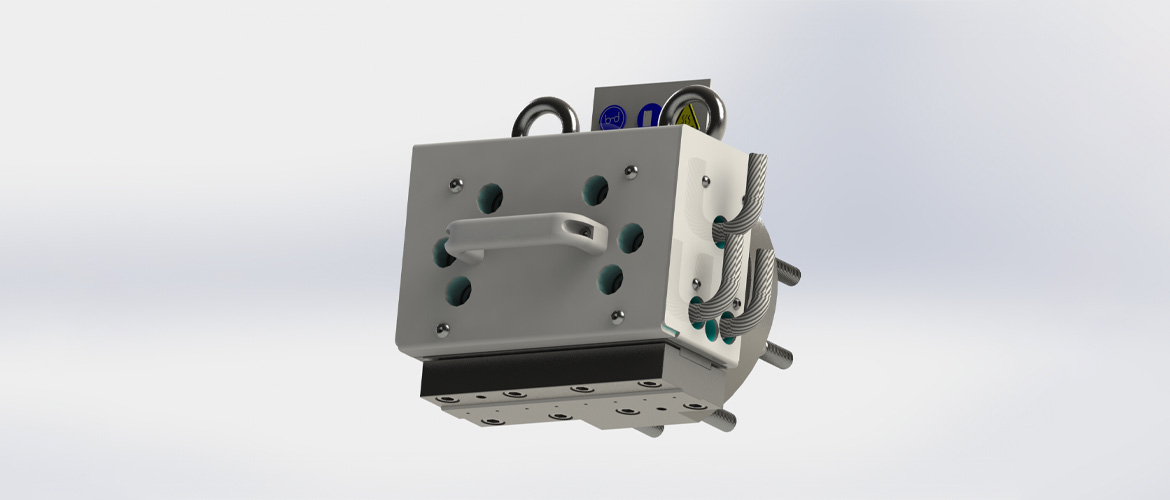

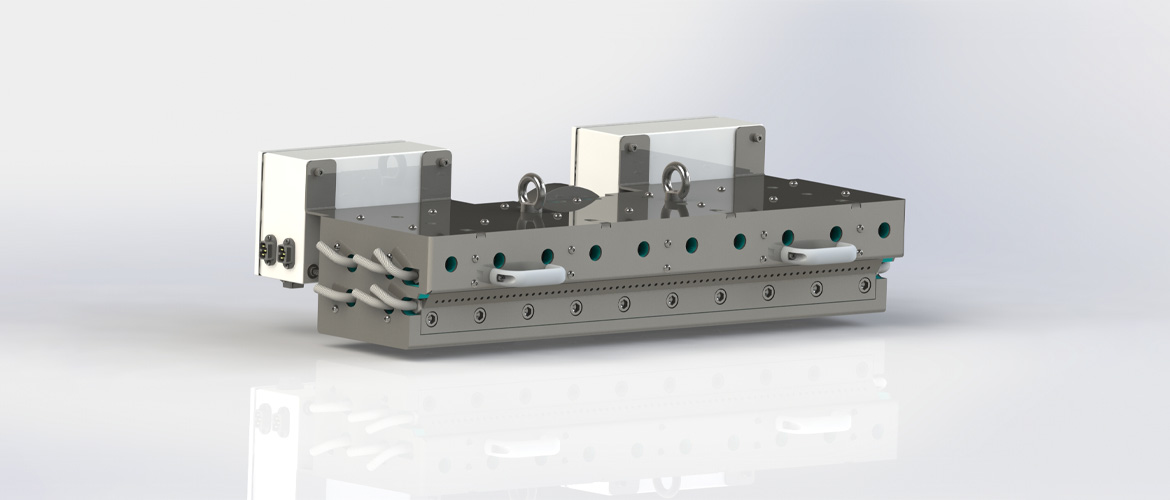

Adaptec die heads are manufactured in one or two part execution and are mainly consisting of one or two part manufactured die head, prepared for connection to upstream installed unit. The die head is equipped with a changeable strand die plate which could be executed for screwable or quick (de)-installation.

Advantages

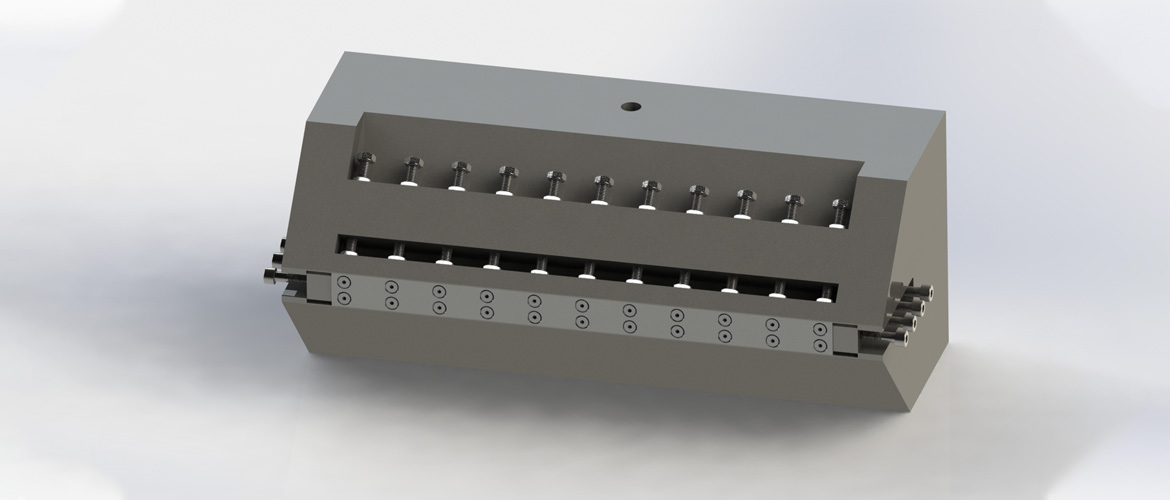

- optimized for relevant product viscosities in order to equalize strand flow by our special melt flow channel geometric execution

- executed with polished flow channel surfaces, hardened / coated, according to necessary requirements

- short change over times, especially in case of product - and color changes with resulting costs (especially in case of multiple parted execution / quick connection at die head)

- simplyfied cleaning by free access of all melt flow channel areas

- executed with heating elements, completely delivery and prepared for installation / assembly